Industry 4.0 – the fourth industrial revolution took off once there was ease of global connectivity through SIM cards and such like for automated availability of data anywhere, anytime from manufacturing equipment directly. That certainly gives us possibility of quicker corrective actions through Predictive / Adaptive system … fetching certain level of benefits to the Business.

Then came a question …. What Next?

- Artificial Intelligence could be applied … OK Great but do we feel the need for it in manufacturing processes?

- With much more Data up our sleeves we ought to become much wiser … looks good and logical argument; but it is a very long shot … with not much tangibles outcomes being visible for now.

- Rightly or wrongly, Industry 4.0 has been paving ground for “total automation”; but if machines do everything automatically …. What will the human population do? What kind of employment opportunities would be there in future? It is a big socio-economic issue looming large.

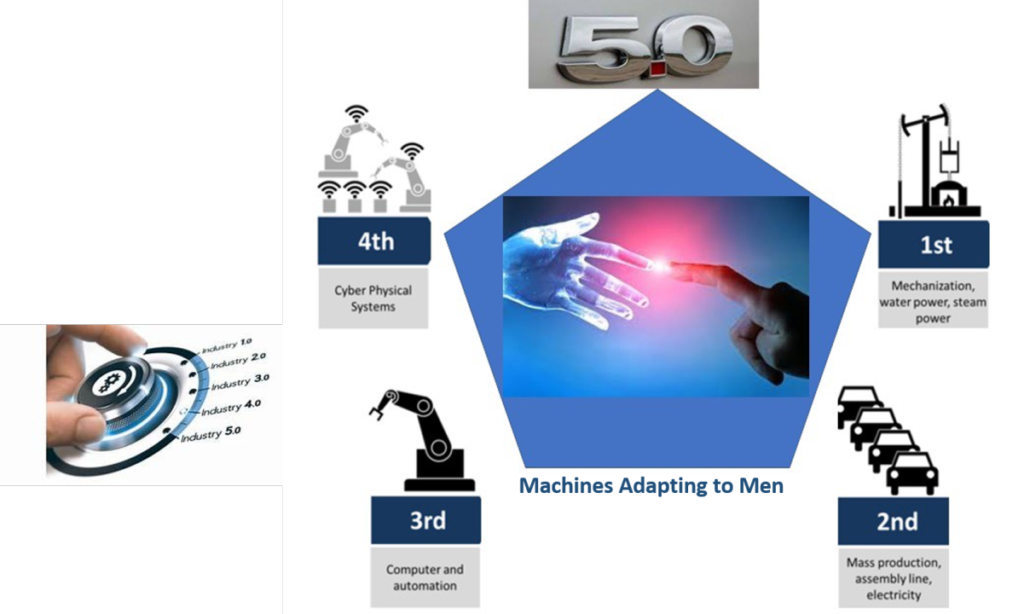

- Beyond Industry 4.0 there could always be some Industry 5.0; but what would be its distinguishing feature?

- “Mass Customization” is one catchword being associated with it already … but then ‘Additive Manufacturing’ is very much a pillar of Industry 4.0 also, and so in a way mass customization has been there; even as it has been understated in overwhelming “mass production” mind set in Industry and relatively slower proliferation of metal 3D Printing.

Drivers for Industry 5.0

- There are areas in manufacturing where automation is simply not feasible e.g., Electrode Arc welding with Robot. In best of automotive assembly lines Robots do assembly line tending BUT assembly is still being done manually.

- Look at any premium segment products like Khadi silk, Banarasi Saree, Vintage Rolls Royce, Leather Upholstery, Handmade Cookies / Cakes / Wines , Picasso Painting, sculptures, embroidery …. All of them use human touch – feel, dexterity, creativity and adaptive working.

- Would you like to go to a star restaurant if chef happens to be a Robot there?

- Automation could only produce “run of the mill” lower cost mass produced stuff with absolute consistency and repeatability … but what to do where “variability” is a value?

- AI can do many things but it cannot make a machine to do poetry (shero-shairi) on spur of moment to respond to the context. All it could do is like IVR or typically like railway announcements computer assembled through “cut and paste” technology.

- So far men has adapted to be able to operate a machine by learning their cryptic codes, commands and unnatural processes. What if …. Machines adapt to human behaviour and learn to work with human beings much like a friendly colleague.

- Human Friendly Automation will be the key differentiator of Industry 5.0

What is required for it?

- Machines and Automation which are safe enough to work besides human operatives

- Human Touch , Speech and Gesture Recognition by machine

- AI based learning of individual operatives reaction pattern … differences in exclamations, vernacular, moods and behaviour pattern to decipher between “Yes” and “No”

Whatever is best done by human effort shall be done by them along with rest being done through machines and automation.

Industry 5.0 hinges around building a friendly synergy across man and machine.

AVINASH KHARE