Industry 4.0 has become a blind men’s elephant:

- On one hand there are manufacturing equipment makers who are providing built-in sensors and dashboards for OEE, Utilization, Energy Monitoring, Preventive & Predictive Maintenance escalation utilities.

- On other side there are Communication, Networking and CLOUD ware sellers

- Then there are also some “Software Solution Providers” who claim to integrate and customize standard CRM, ERP, Scheduler, Material Management and Logistics and Performance Management System etc. extending right up to cell phone based apps.

There are host of Trainers who focus on selling their respective wares … making it look like “plug and play” commodity which it is not. It deserves active participation of user, which is often not forthcoming.

What the market is missing is perhaps the focus on user’s perspective and Holistic Business View:

- CNC Machine makers only focus on machine utilization, tool life and maintenance but they cannot cover manual assembly and quality aspects.

- Welding equipment makers show only welding related parameters but not inventory, distortions while welding and plasma cutting.

- Simulators mostly stay in their theoretical virtual world and rarely do they recalibrate it with the reality.

- Quality people talk nothing beyond quality KPIs

- Senior Management often treats I4.0 like ISO Certification “icing”; which is mandatory and required for flaunting.

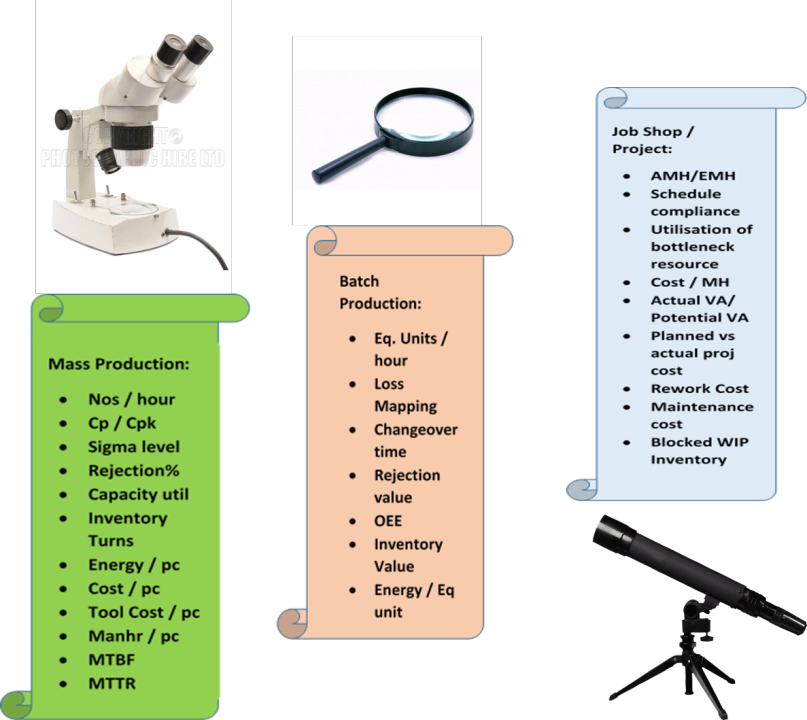

What should be monitored for Industry 4.0 ?

- Something which is relevant for the kind of manufacturing user has (refer picture)

- Something which is really the bottleneck / pain point

- Something which is actionable or which could provide actionable intelligence

- Something which would help predicting better for the future

- Something where adaptive correction could be done in running process

Often there is tendency to blindly go for initiatives / monitoring which are considered to be “universal” Industrial Best Practices … and often Industry 4.0 is being sought and sold for deployment for those.

AVINASH KHARE