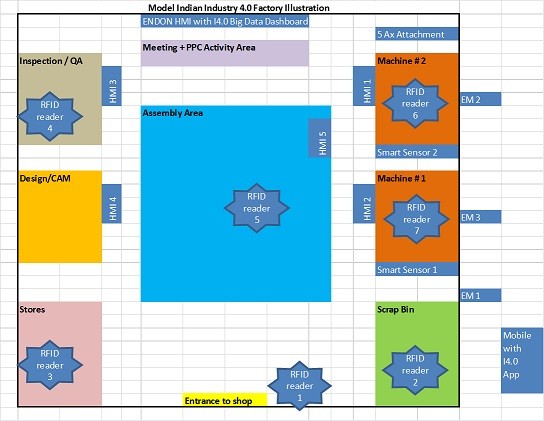

Usually Indian factories approach implementation of Industry 4.0 peace meal, with standalone clichéd applications like OEE, Predictive Maintenance, Productivity, Dashboards on mobile apps, Energy Monitoring etc. Here is a representative illustration of what all could be possible with a modest investment in a small manufacturing unit which covers data automation in most of manufacturing related parameters.

- If entrance to shop floor has RFID reader and all material and men crossing gate wear RFID tags; the computer system for the factory could keep track on all material receipts / despatches as well as attendance of employees automatically.

- Stores gate has another RFID reader to track material issues and receipts and inventory tracking could get automated.

- Scrap bin of shop also can automatically inform what all got scrapped (including direct material, tools and machinery spares ) hence need to be replaced.

- There are two machines which identify the operative, fixture, tool as well as job on the table; and based on Gantt chart it could pick up the right CNC Program and execute. The machine could automatically update the Gantt chart also and flag any major deviations and estimated time overrun.

- In addition the machines have smart sensor to monitor vibrations and vibration spectrum signature for mass production job. Any significant deviation could flag “abnormal process condition” that could affect quality as well as machine condition deterioration.

- Energy meters are there to monitor overall energy consumption as well as specific energy consumption for mass produced jobs. They could also flag significant change in machine condition. HMIs at machine are used to type in the “Loss Code” whenever machine did not cut for significant time. They are also used for reporting maintenance issues and work done by maintenance team at the machine – thus automating “Machine History Card”

- Automated dashboard is used for review meetings and for Production Planning and Control.

- QA reports get linked to identified entity and HMI is used for visual observations

- Design / CAM cell runs simulation for collision detection if any attachments are used at CNC Machines

- Assembly area identifies presence of all parts in the area and HMI is used for communicating any issues / instructions, guidelines etc.

- Assembly area could utilize Cobot to work with human operative

- Augmented Reality could be used to display specific work instructions / work guidelines driven by identified context at HMIs and Goggles.

- Since there are so many RFIDs all over it is possible to generate the spaghetti diagram for men /material for Kaizen exercise as well as for curbing unnecessary movements.

- Use of CLOUD may be optional

All aspects of Industry 4.0 can be thus deployed with above, with relatively modest investment towards sensors and hardware; provided the system integration gets done to customize it for overall effectiveness.